Telexistence to Begin Proof of Concept to Introduce Its New Robot into Logistics Facilities; Partnership with Nichirei Logistics and SENKO

Telexistence Inc. (Headquarters: Chuo-ku, Tokyo; CEO: Jin Tomioka; hereafter TX) , Nichirei Logistics Group, Inc. (Headquarters: Chuo-ku, Tokyo; President: Kazushiko Umezawa; hereafter Nichirei Logistics), and SENKO Co., Ltd. (Headquarters: Kita-ku, Osaka; President: Yasuhisa Fukuda; hereafter SENKO) jointly started a proof of concept for the introduction of TX robot to the logistics facilities of Nichirei Logistics and SENKO, with the aim of developing new logistics operations centered on hybrid control robot technology that combines automatic control by TX’s proprietary AI system with remote control by operators.

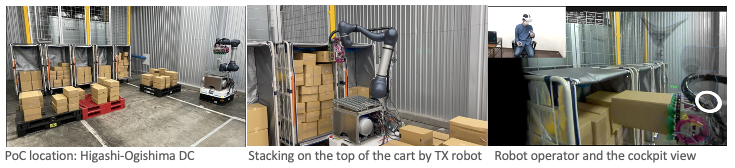

As a first step, a demonstration was conducted today in the refrigerated area of a Nichirei Logistics distribution facility, where TX’s remote-controlled robot performed mixed loading onto a basket cart. In addition, a demonstration test is scheduled for the fall of 2022 at SENKO’s logistics facility for a major retailer network.

TX robot for logistics facilities consists of a collaborative robot arm, an AGV (Autonomous Guided Vehicle), an end-effector, and a remote-control system (*1). General palletizing/de-palletizing robots require anchoring to the floor, which limits the robot’s operating location or requires additional material handling equipment to the process before or after the robot’s work. On the other hand, TX robot is equipped with an AGV and a remote-control system, and all power is supplied from the AGV’s built-in battery, so they can be operated in different locations or can perform tasks that require movement. Also, the remote-control operator visually checks the object to grasp and the stacking location. This allows for optimal grasping and placement according to case size. Even when complex tasks are required, such as cold-covered basket carts, the robot can perform mixed stacking while maintaining optimal loading efficiency.

(*1) Collaborative robot arms and AGVs are manufactured by third-party manufactures.

TX aims to leverage its Augmented Workforce Platform (AWP) (*2) to verify the improvement of the working environment and productivity in the logistics industry, where labor costs are soaring and chronic labor shortages are becoming more serious, by having the robot replace the work in refrigerated areas that place a heavy burden on human body. Solving labor issues in the logistics industry through AWP is an initiative consistent with TX’s corporate mission of liberating workers from all physical labor tasks. TX will continue working toward full-scale implementation of its robots into logistics facilities.

(*2) a platform that enables robot control with an optimal mixture of remote-control and automated control by AI

Nichirei Logistics focuses on operational innovation to address labor shortages, reduce the burden on workers, and make on-site work “doable by anyone,” and is building an optimal work system that takes advantage of the characteristics of both humans and machines. In this PoC, robots placed in the refrigerated area will be remote-controlled by operators from the office to verify the possibility of remote work and construction of a stress-free work environment in distribution center operations. Nichirei Logistics will continue to actively promote the introduction of cutting-edge technologies and the digitization of operations to realize sustainable logistics that support our customers’ supply chains.

SENKO introduced a depalletizing arm robot in 2014 and has since been actively introducing AGVs and other labor-saving equipment. The most important feature of TX robot is its mobility. Unlike conventional robots that are difficult to move once installed, TX robot can move according to the convenience of the business, dramatically increasing the operating time of the robot. Also, the constant monitoring by operators via remote-control system will enable quick response to problems. In addition, resolving labor shortages in warehouse operations is an urgent issue. SENKO aims to reduce burdensome manual loading and unloading tasks especially during summer by introducing robots, while at the same time providing people with a work-life balance and a way of working that is not limited by time or location.

■ Outline of Proof of Concept by Nichirei Logistics and TX

1. Date : March 4, 2022

2. Location : Logistics Network Inc. Higashi-Ogishima Distribution Center (100% subsidiary of Nichirei Logistics)

Press Kit:TX Press Kit 2022.03.04 Logistics PoC

< Nichirei Logistics Group Inc.>(https://www.nichirei-logi.co.jp/)

Nichirei Logistics Group Inc. consists of a logistics network business centered on transportation and delivery, TC, and 3PL; a regional storage business that handles refrigerated warehouse functions; overseas operations in Europe, China, and ASEAN countries; and an engineering business that handles everything from planning, design, and construction to maintenance management of refrigerated facilities. It is a No. 1 low-temperature logistics company group in Japan. Our goal is to spread the high-quality low-temperature logistics we have cultivated as a global standard.

Address: 6-19-20 Tsukiji, Chuo-ku, Tokyo

Representative: Kazuhiko Umezawa, President

Date of Inception: April 1, 2005

<SENKO Co., Ltd.>(https://www.senko.co.jp/jp/)

SENKO Co., Ltd. offers a wide range of services, including rail & marine transportation, warehousing, in-plant logistics, and international logistics, with nationwide network car transportation at its core. We support our customers in building SCM with logistics systems that make full use of the latest IT, including comprehensive services at distribution centers with multiple functions such as storage, delivery, distribution processing, and information distribution, as well as the design and operation of optimal systems that lead to efficiency in logistics.

Address: 1-1-30 Oyodonaka, Kita-ku, Osaka City

Representative: Yasuhisa Fukuda, President

Date of Inception: April 15, 2016